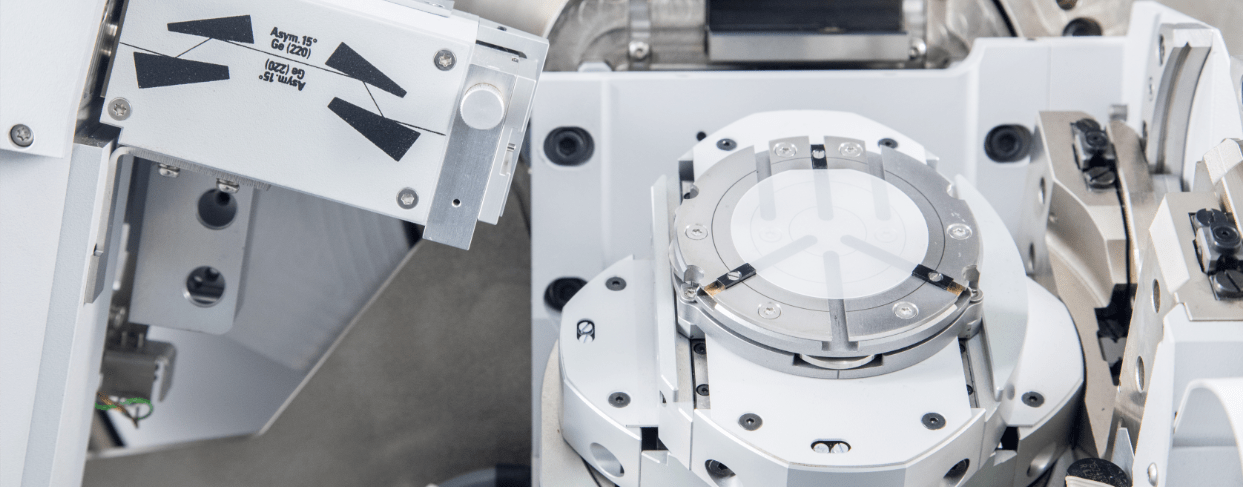

Combining the benefits of MOCVD & RPCVD in a single platform

RPCVD offers manufacturers significant performance and cost advantages by growing group III nitrides such as gallium nitride and indium gallium nitride at lower temperatures, with the additional capability of hybrid MOCVD & RPCVD devices.

Lower temperature for brighter devices

Low temperature growth provides device manufacturers many unique performance and technology enabling benefits.

By growing critical temperature sensitive device layers with increased quality, we can help you improve your device efficiency, reduce resistivity and performance losses and many other benefits: